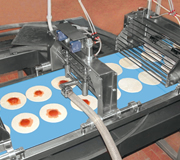

Superpizza TR3 LS group

This group has been specifically engineered for largescale production. It is able to produce dough with round shape or with other geometric shapes. The dough can be placed directly on the pans or on conveyor belts for additional stuffing.

The shape of the dough is determined by an easy-to-remove mold. The continuous sheeting process reduce the dough to the required thickness maintaining the good quality of the dough.